2020 Laskey Charrette

2020-01-28 • Sam Fox School

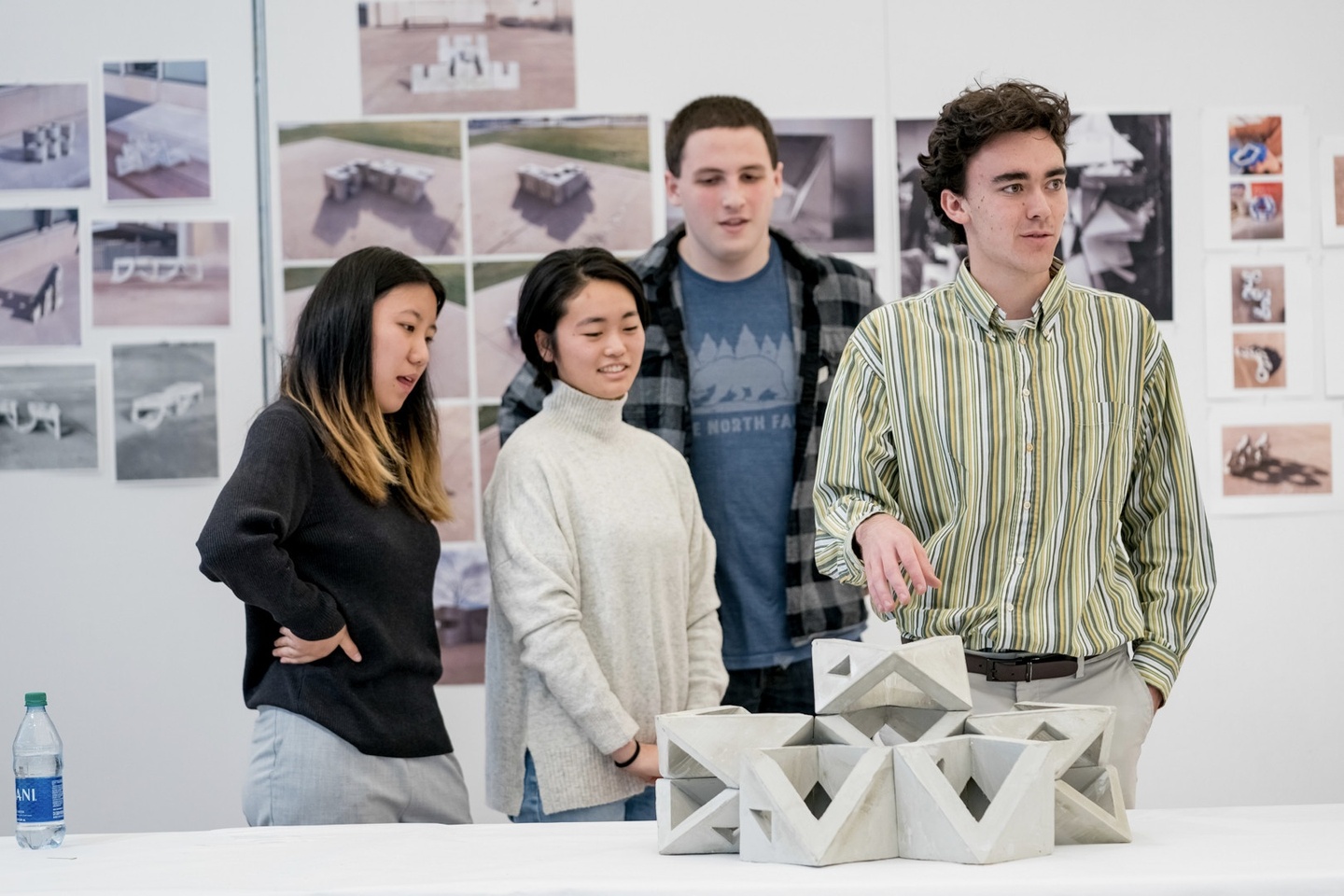

The team of Lisa Chen, Risako Nozaki, Andy Entis, and Spencer Derthick took first place for Model T. Photo: Whitney Curtis.

We are pleased to announce the winners of the 2020 Laskey Charrette:

1st Place ($1,500)

Model T: Lisa Chen, Spencer Derthick, Andy Entis, and Risako Nozaki

Honorable Mentions

Folds & Gaps: Connor Merritt, Annika Pan, and Yuwei Yang

Divergence: Malik Gaye, Christa Hua, Allen Liang, and Caleb Ullendorff

Circuit: Caroline Denk, Xiaowen Ma, and Emily Rupright

Second-year architecture students in the Sam Fox School participated in this intensive, weekend-long workshop that honors emeritus professor Leslie Laskey’s 35-year tenure on the architecture faculty. The charrette is presented annually by Studio L in collaboration with the College of Architecture and Graduate School of Architecture & Urban Design. The competition, which took place January 24-26, was moderated by Aki Ishida, associate professor of architecture at Virginia Tech and founder of Aki Ishida Architect.

Design Brief: Light Modulating Concrete Wall

The 2020 Laskey Charrette design challenge asks you to experiment with modular assembly in cast concrete. Build a set of concrete modules that are stacked to make a wall that turns a corner. The wall must allow light to pass through.

The wall must be assembled out of 8 identical modular units. Each module should have an exterior volume of a 6" x 6" x 6" (216 cubic inches), with a minimum void-to-solid ratio of 65 to 35. In other words, in each module, the concrete must constitute 75 cubic inches or less.

The light can pass through between modules, or through an aperture(s) in the module.

The wall must stand on its own without leaning on or being supported by something else.

Use 3/16" foamcore to build your molds. Corners must be tightly glued, then sealed with masking tape to prevent leakage. Remember that cast concrete will pick up every joint mark or seam inside the mold, so make the mold surfaces as clean as possible. Coat the inside with polyurethane for an easier release.

Reinforce the outside of your foamcore mold (see example images) as needed. The cement mixture will push against the mold and expand, and reinforcement will prevent warping and collapsing of molds and keep corners square.

On Sunday, each team will present the following:

Your cast concrete wall arranged on a table.

Printed posters with photos documenting the casting process and the finished wall. Experiment with various stacking configurations, and photograph them under varying light conditions, preferably daylight, to show how light passes through the apertures. Layout and print on 36" wide paper (any configuration using 36" module). You may also include process sketches and drawings.

Keep these questions in mind as you make the molds and cast:

Is the wall stable while allowing light to pass through? How well do the modules stack or interlock with each other?

Are the molds and the casts well crafted? Do the casts hold their shape without falling or breaking apart? How clean are the corners?

How well do the photographs capture the qualities of light, the wall as a whole, details, and the process?

How do you work effectively as a team? How do you collectively incorporate the best ideas from its members and delegate tasks? By design, a successful execution of this project is only possible with good team work.